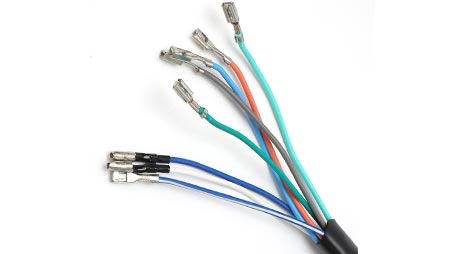

JCW-2TN Multiconductor Sheathed Cable Strip and Crimp Machine

High-level model, servo-motorized, ultra-robust and precise

Specialist in processing multicore cable

Multicore cables are custom-designed and built to meet unique product needs, we design and build the JCW-2TN stripping and crimping machine for this application. This stripping and crimping machine adopts 2 sets of servo motors to ensure precise wire transfer and wire stripping. With TBI two-way grinding precision ball screw and HIWIN guide rail, each movement position of the wire is accurately controlled to ensure that the wire is in the correct position every crimping.

The fully programmable electronic JCW-2TN stripping and crimping machine offers you high performance and high output. Except for the wire stripping length, the terminal crimping depth is adjustable easily and precisely via a 7" color touch screen.

The waste collector ensures clean work bench, all of the stripped insulation scrap will be collected by the air inhale equipment.

Reliable and stable

Unique U-shaped wire clamp offers ultra wide space for long cables. New designed wire clamping station offers neat wire alignment. The clamping force is adjustable to avoid damage to the wire insulation.

The JCW's smart-designed side-feed crimp applicator allows the process of extremely fine wires, each wire will be separated before and after crimping.

All parts of the whole machine use anti-corrosion materials, ultra-robust design, 225KG net weight, attention to detail and the pursuit of quality to create the perfect JCW-2TN wire stripping and crimping machine.

The stripping length of the outer sheath must be over 32mm.

![Wire Stripping Twisting & Bootlace Ferrule Crimping Machine [ 4mm² ]](/data/thumb/res/en/20210829/2d8160410db52470.jpg_20210829092500_800x800.jpeg)

![Fully Servo Motorized 16mm O.D. Battery Cable Cutting and Stripping Machine [ 50 mm² ]](/data/thumb/res/en/20230610/JCWELEC-CS07C-50SQ-CABLE-CUTTING-STRIPPING-MACHINE_931e1689.jpg_20230610093111_800x800.jpeg)

![12mm O.D. Automatic Battery Cable Cutting Machine [ 8 Rollers ]](/data/thumb/res/en/20241017/jcwelec-cs05-cable-cut-strip-machine_9c0162da.jpg_20241017144902_800x800.jpeg)